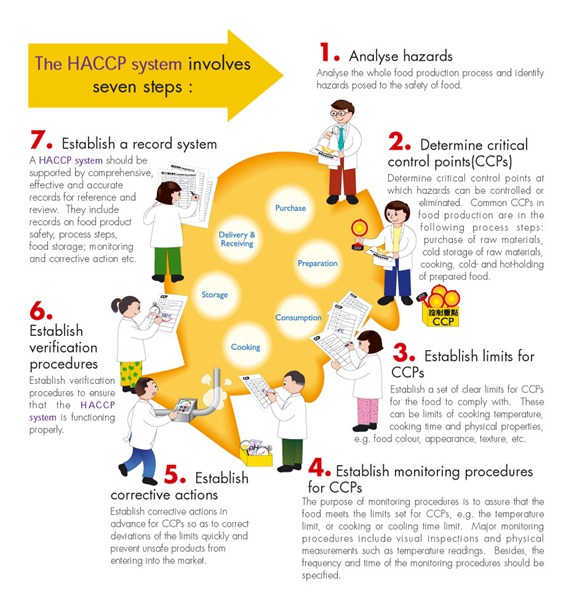

HACCP

(Hazard Analysis Critical Control Point) is the systematic preventative approach to food safety. It addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection. This approach has significant benefits to organizations operating within the food supply chain as it enables them to determine key controls over processes and concentrate resources on activities that are critical to ensuring safe food. Retailers, the food industry and Government in particular are concerned about ensuring that food is produced safely and that the consumer has confidence in the product. This has led to an increase in legislation over time that has focused upon ensuring safe systems of food production. In Canada, HACCP certification is a voluntary program for food companies that only distribute product within their own province. For those who wish to distribute nationally or internationally it then becomes a requirement. Farm Fed has been certified since 1996 and undergoes yearly audits to ensure compliance

Hygiene

Farm Fed staff undergo strict yearly training on personal health and hygiene. Each new employee is also required to follow company guidelines as laid out in the policy manual and are monitored closely

7 Steps

Seven basic principles are employed in the development of HACCP plans that meet the stated goal. These principles include hazard analysis, CCP identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping and documentation.